From beginner’s basics to pro, discover the perfect electrical testers for your projects.

Greetings and a warm welcome. We hope you’ve been finding our previous posts insightful, including “How to Supercharge Your Online Presence with the Power of Search Engine Optimization – Part 9.” and “Qwixby’s Guide to Website Development for Small Businesses.“

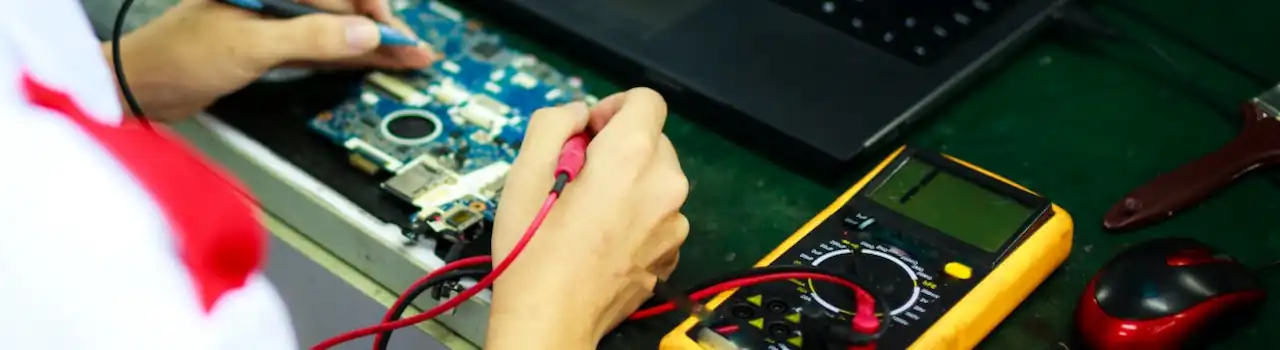

In this instalment, we shift our focus to an essential aspect of electrical work – Electrical Testers. Whether you’re a seasoned professional or just starting on your electrical journey, understanding the right tools for the job is crucial.

The purpose of this guide is to empower you with the knowledge needed to make informed decisions when selecting Electrical Testers. From voltage testers to insulation meters, we’ll explore the key tools and their applications, ensuring you have a solid understanding of their roles in electrical work.

Throughout this blog post, we’ll delve into various types of Electrical Testers, discuss safety considerations for electrical testing, guide you on choosing the right voltage tester, and more. The emphasis will be on providing practical information for your specific needs.

So, whether you’re looking to enhance your toolkit or just beginning to explore the world of electrical work, read on to discover the perfect electrical testers for your projects.

Types of Electrical Testers

Voltage Testers

Voltage testing is a fundamental aspect of electrical work, serving as a primary diagnostic tool to ensure safety and functionality. Understanding the reasons for voltage testing is crucial for any electrician or DIY enthusiast.

Reasons for Voltage Testing in Electrical Work

Voltage testing is conducted for several critical reasons:

- Safety Verification: Before starting any work on an electrical system, it’s imperative to verify that circuits are de-energized. This prevents the risk of electric shock and ensures the safety of those working on the system.

- Equipment Functionality: Voltage testing helps confirm that electrical equipment, such as outlets and switches, is receiving the correct voltage. This ensures optimal performance and prevents potential damage to appliances.

- Troubleshooting: When electrical issues arise, voltage testing is essential for identifying the source of the problem. Whether it’s a faulty wire or a malfunctioning device, voltage testers help pinpoint issues quickly.

Different Types of Voltage Testers

When it comes to voltage testers, there are various types catering to different needs and preferences. Here are the main types:

- Non-Contact Voltage Testers: These testers detect the presence of voltage without direct contact with the conductor. They are convenient for quickly checking if a wire or outlet is live without physically touching it.

- Contact Voltage Testers: These testers require direct contact with the conductor to determine voltage. They often come with probes that need to touch the wire or surface being tested.

- Proximity Voltage Testers: Using advanced technology, proximity testers can detect voltage even when the tester is close to, but not in direct contact with, the electrical source. This adds an extra layer of safety and convenience.

Safety Considerations when Using Voltage Testers

While voltage testers are indispensable, safety should always be a top priority. Here are key safety considerations when using voltage testers:

- Personal Protective Equipment (PPE): Wear appropriate PPE, including insulated gloves and safety glasses, to protect against potential shocks.

- Regular Calibration: Ensure that your voltage tester is regularly calibrated to maintain accuracy in readings.

- Inspect the Tester: Before each use, inspect the voltage tester for any visible damage. A damaged tester may provide inaccurate readings and compromise safety.

- Test on Known Sources: Before relying on a voltage tester, test it on a known live source to verify its functionality.

By understanding the importance of voltage testing, choosing the right type of voltage tester for your needs, and prioritizing safety, you set the foundation for successful and secure electrical work.

Amperage and Wattage Load Testers

Load testing is a critical aspect of electrical systems, providing valuable insights into the performance and capacity of circuits and devices. Let’s explore the significance of load testing, differentiate between amperage and wattage load testers, and understand the scenarios where each type is essential.

Understanding the Need for Load Testing in Electrical Systems

Load testing involves applying a controlled electrical load to a system to assess its performance under normal and peak conditions. This process is essential for several reasons:

- Capacity Assessment: Load testing helps determine the maximum capacity of electrical circuits, ensuring they can handle the anticipated load without tripping breakers or causing overheating.

- Identifying Weaknesses: By subjecting a system to varying loads, load testing can reveal weaknesses, such as voltage drops or fluctuations, that might affect the overall efficiency of the electrical network.

- Device Compatibility: Load testing is crucial when introducing new electrical devices to a system. It ensures that the existing infrastructure can support the additional load without compromising safety or performance.

Differentiating Between Amperage and Wattage Load Testers

Amperage Load Testers

Amperage load testers measure the current flowing through a circuit and are particularly useful for:

- Circuit Overload Assessment: Amperage testing helps determine if a circuit is overloaded by measuring the current draw. This is crucial for preventing overheating and potential damage to wires and devices.

- Identifying Faulty Components: By assessing the current draw of individual components, such as motors or appliances, amperage testers assist in identifying faulty or inefficient devices.

Wattage Load Testers

Wattage load testers, on the other hand, measure both voltage and current, providing a comprehensive view of the power consumption. They are essential for:

- Power Consumption Analysis: Wattage testing allows for a detailed analysis of how much power a device or circuit consumes, helping users make informed decisions about energy usage.

- Determining Efficiency: By calculating the power factor (the ratio of real power to apparent power), wattage testers reveal the efficiency of electrical devices and systems.

Applications and Scenarios

Amperage Load Testers are Essential in:

- Residential Settings: Assessing the load on household circuits to prevent overloading.

- Industrial Environments: Monitoring the current draw of heavy machinery to identify potential issues.

Wattage Load Testers Shine in:

- Energy Audits: Analyzing the power consumption of various devices for energy-efficient choices.

- Commercial Spaces: Ensuring that office equipment operates optimally within the electrical system’s capacity.

In conclusion, both amperage and wattage load testers play crucial roles in maintaining the health and efficiency of electrical systems. Understanding when to use each type ensures comprehensive testing, helping you make informed decisions about capacity, device efficiency, and overall system performance.

Battery Testers

Batteries are the lifeblood of countless electronic devices, and ensuring their reliability is paramount. In this section, we’ll explore the importance of testing batteries, the different types of battery testers available – including voltage testers and conductance testers – and provide guidance on selecting the right battery tester for specific requirements.

Testing Batteries in Various Electronic Devices

The performance of electronic devices heavily relies on the condition of their batteries. Regular testing is crucial for the following reasons:

- Device Reliability: Testing batteries ensures that electronic devices operate reliably. This is particularly important for critical equipment where downtime is not an option.

- Preventing Unexpected Failures: Battery testing helps identify weak or failing batteries before they cause unexpected device failures. This proactive approach is essential for maintaining uninterrupted functionality.

- Maximizing Battery Life: Understanding the condition of batteries allows users to take appropriate measures to extend their lifespan. This is cost-effective and reduces the environmental impact of frequent battery disposal.

Different Types of Battery Testers

Voltage Testers for Batteries

- Principle: Measure the voltage output of a battery.

- Application: Quick and straightforward, suitable for determining whether a battery has sufficient voltage to power a device.

- Limitation: May not provide a comprehensive assessment of a battery’s overall health.

Conductance Testers for Batteries

- Principle: Assess the battery’s ability to conduct current.

- Application: More comprehensive than voltage testing, conductance testers offer insights into a battery’s internal resistance and overall health.

- Advantage: Effective for testing batteries in a loaded condition, providing a more accurate assessment.

How to Choose the Right Battery Tester

Choosing the right battery tester involves considering the specific needs and characteristics of the batteries in question. Here’s a guide to help you make an informed decision:

- Battery Type: Ensure the tester is compatible with the types of batteries you commonly encounter (alkaline, lithium, NiMH, etc.).

- Testing Conditions: Consider where and how you’ll be testing batteries. Some testers are more suitable for on-the-go testing, while others are designed for more controlled environments.

- Additional Features: Look for extra functionalities such as battery voltage range, internal resistance measurement, and compatibility with rechargeable batteries.

- Ease of Use: Choose a battery tester that is user-friendly and provides clear readings. This is especially important for those not well-versed in technical details.

- Budget Considerations: While there are high-end battery testers with advanced features, there are also more budget-friendly options that might suit your needs.

By understanding the importance of battery testing, recognizing the types of battery testers available, and considering your specific requirements, you can confidently choose the right tool to ensure the optimal performance of the batteries powering your electronic devices.

Circuit and Receptacle Testers

Circuit and receptacle testers are invaluable tools for maintaining electrical safety and functionality in both home and industrial settings. In this section, we’ll explore the significance of circuit and receptacle testing, delve into the functionalities of these testers, and discuss common issues identified along with troubleshooting tips.

The Significance of Circuit and Receptacle Testing

Home Applications:

- Safety Assurance: Regular testing ensures that electrical circuits in homes are safe and free from potential hazards, reducing the risk of electrical fires or shocks.

- Appliance Compatibility: Testing receptacles helps homeowners confirm that appliances are connected to properly functioning circuits, preventing damage due to faulty wiring.

Industrial Applications:

- System Integrity: In industrial settings, the integrity of electrical systems is crucial. Testing circuits and receptacles ensure continuous and safe operation, preventing costly downtime.

- Compliance: Many industrial facilities are subject to electrical codes and regulations. Routine testing helps maintain compliance with safety standards.

Functionalities of Circuit and Receptacle Testers

Circuit Testers:

- Live/Dead Indication: Circuit testers determine whether a circuit is live or dead, providing a quick assessment of its status.

- Wiring Issues: These testers can identify common wiring problems such as open circuits, short circuits, or reversed polarity.

Receptacle Testers:

- Grounding Checks: Receptacle testers assess the grounding of outlets, a critical factor for safety and the proper functioning of electronic devices.

- Correct Wiring: They indicate whether the wiring is correct or if there are issues like reversed hot and neutral wires.

Common Issues Identified by Circuit and Receptacle Testers

- Open Circuits: Occur when a circuit is incomplete, leading to a lack of power in the connected devices. Testers can identify the specific location of the open circuit.

- Short Circuits: These occur when two conductors with different potentials come into contact, leading to excessive current flow. Circuit testers can pinpoint the location of the short.

- Grounding Problems: Receptacle testers can detect issues with grounding, such as missing or improperly connected ground wires, which are critical for preventing electrical shocks.

Troubleshooting Tips

- Check for Loose Connections: Tighten any loose connections identified by the tester to ensure a secure and reliable electrical connection.

- Inspect Wiring: Examine the wiring for signs of damage or wear. Replace any compromised wiring to prevent future issues.

- Consult a Professional: If the tester indicates complex issues or if you’re unsure about the results, it’s advisable to consult with a qualified electrician for a thorough inspection and necessary repairs.

By regularly employing circuit and receptacle testers, both homeowners and industrial professionals can maintain electrical safety, identify potential issues early on, and take corrective measures to ensure the reliability of electrical systems.

Ohmmeter

Ohmmeters are indispensable tools in the realm of electrical work, providing a direct measure of electrical resistance. In this section, we’ll introduce ohmmeters, delve into their role in measuring resistance, explore practical applications in troubleshooting circuits, and offer tips on using ohmmeters effectively.

Ohmmeters are instruments designed to measure the electrical resistance of a component or a circuit. Resistance, measured in ohms (Ω), is a fundamental property that defines how much a device or material opposes the flow of electric current. The key role of ohmmeters includes:

- Resistance Measurement: Ohmmeters provide a quantitative measure of the resistance in a circuit, allowing electricians and technicians to assess the health of components.

- Continuity Testing: Ohmmeters can be used to check for continuity in a circuit, determining if a path exists for electric current to flow.

Practical Applications of Ohmmeters for Troubleshooting

Identifying Faulty Components:

- Resistors: Ohmmeters help assess the condition of resistors by measuring their resistance. A significant deviation from the specified value may indicate a faulty resistor.

- Switches: Ohmmeters can verify the continuity of switches, ensuring they make proper contact in both open and closed positions.

Checking for Short Circuits and Open Circuits:

- Short Circuits: Ohmmeters detect short circuits by measuring very low resistance between two points where it should not exist.

- Open Circuits: Conversely, an extremely high resistance reading indicates an open circuit, where the path for current flow is interrupted.

Tips on Using Ohmmeters Effectively

- Power Off: Ensure the circuit or device being tested is de-energized before connecting the ohmmeter. This prevents damage to the ohmmeter and ensures safety.

- Select the Right Range: Choose the appropriate ohm range on the ohmmeter. Start with a higher range and then switch to lower ranges for more accurate readings.

- Zero the Ohmmeter: Before making a measurement, zero the Ohmmeter to compensate for any internal resistance.

- Isolate Components: Disconnect components from the circuit before testing to isolate and accurately measure their resistance.

- Interpreting Readings:

- Low Resistance: Indicates a good conductor or a short circuit.

- High Resistance: Suggests an open circuit or a component with high resistance.

- Infinity (∞): Displayed for open circuits or when there is no continuity.

Ohmmeters are invaluable tools for anyone working with electrical circuits. By understanding their role in measuring resistance, applying them to troubleshoot circuits, and following best practices for effective usage, individuals can confidently diagnose and resolve electrical issues, ensuring the integrity and reliability of their electrical systems.

Multimeter

Multimeters are the Swiss Army knives of electrical testing, offering a multitude of functionalities in a single device. In this section, we’ll provide a comprehensive overview of multimeters, explore the different modes and measurements they provide, and discuss key features to consider when selecting a multimeter for specific tasks.

Multimeters and Their Versatile Functionalities

A multimeter, short for multiple meters, is an electronic tool used to measure various electrical parameters. It typically combines several measurement functions into one portable device, making it an essential tool for electricians, engineers, and DIY enthusiasts. The versatile functionalities of a multimeter include:

- Voltage Measurement (Volts): Measures the electrical potential difference between two points in a circuit.

- Current Measurement (Amperes): Determines the flow of electric current through a circuit.

- Resistance Measurement (Ohms): Measures the opposition to the flow of current in a circuit.

- Continuity Testing: Checks if a circuit is complete by audible signalling if a path for current flow exists.

- Diode Testing: Verifies the functionality of diodes in electronic circuits.

- Capacitance Measurement (Farads): Measures the ability of a component to store electrical charge.

Different Modes and Measurements Provided by Multimeters

Modes:

- Volts Mode: Measures direct current (DC) and alternating current (AC) voltage.

- Amps Mode: Measures DC and AC current.

- Ohms Mode: Measures resistance in ohms.

- Diode Mode: Tests the functionality of diodes in a circuit.

- Capacitance Mode: Measures the capacitance of capacitors.

Measurements:

- DC Voltage (V): Measures the constant voltage in a circuit.

- AC Voltage (V): Measures the alternating voltage in a circuit.

- DC Current (A): Measures the flow of direct current in a circuit.

- AC Current (A): Measures the flow of alternating current in a circuit.

- Resistance (Ω): Measures the opposition to the flow of current.

- Continuity: Audibly indicates if a circuit has a continuous path.

- Diode Test: Checks the forward voltage drop across a diode.

- Capacitance (F): Measures the ability of a capacitor to store charge.

Features to Consider When Selecting a Multimeter for Specific Tasks

- Auto-ranging vs Manual-ranging: Auto-ranging multimeters automatically select the appropriate measurement range, while manual-ranging requires the user to choose the range.

- Accuracy and Resolution: Higher accuracy ensures precise measurements, and greater resolution allows for finer measurement details.

- Display: A clear, backlit display is essential, especially in low-light conditions.

- Safety Features: Consider features like overload protection, input warnings, and fused current inputs to ensure user safety.

- Build Quality: Choose a durable multimeter with robust construction for longevity.

- Additional Functions: Some multimeters offer advanced features like temperature measurement, frequency measurement, and duty cycle measurement.

- Ease of Use: Intuitive controls and a user-friendly interface make the multimeter more accessible, especially for beginners.

By understanding the broad range of functionalities provided by multimeters, the various modes and measurements they offer, and the key features to consider when selecting one, users can confidently choose the right tool for their specific electrical testing needs.

Whether you’re troubleshooting circuits, testing components, or conducting routine maintenance, a reliable multimeter is an essential companion for any electrical work.

Insulation Tester

Insulation testing is a critical process in the world of electrical maintenance and safety.

In this section, we’ll explore the importance of insulation testing in preventing electrical faults, discuss the types of insulation testers (megohmmeters) and their applications, and provide guidelines on when and how to use insulation testers for optimal results.

Insulation Testing in Preventing Electrical Faults

Insulation is the protective barrier that prevents unintended electrical contact between conductors or between conductors and the ground. Over time, insulation can degrade due to various factors, such as environmental conditions, moisture, and wear and tear. Insulation testing is crucial for the following reasons:

- Preventing Electrical Faults: Insulation testing identifies weaknesses or breakdowns in insulation, helping prevent electrical faults such as short circuits or current leakage.

- Ensuring Equipment Safety: Regular insulation testing ensures the safety of electrical equipment and reduces the risk of electrical shocks or fires caused by faulty insulation.

- Compliance with Standards: Many industries and electrical codes mandate periodic insulation testing to ensure compliance with safety standards and regulations.

Types of Insulation Testers (Megohmmeters) and Their Applications

Types:

- Analog Insulation Testers:

- Application: Suitable for basic insulation testing, they provide a visual analogue display of resistance levels.

- Digital Insulation Testers:

- Application: Offer more advanced features, including digital displays, and data storage, and often come with additional measurement capabilities.

Megohmmeters:

Megohmmeters, commonly known as meggers, are a specific type of insulation tester that measures resistance in megaohms (MΩ). They are widely used for insulation testing due to their high accuracy and sensitivity.

When to Use Insulation Testers:

- Regular Maintenance: Include insulation testing in routine maintenance schedules to identify potential issues before they escalate.

- Equipment Installation: Insulation testing is crucial when installing new electrical equipment to ensure proper insulation integrity.

- Post-Repair Verification: After repairing or replacing components, use insulation testing to verify the effectiveness of the repair and ensure the system’s safety.

How to Use Insulation Testers:

- Power Off: Ensure the equipment is de-energized before connecting the insulation tester.

- Disconnect Devices: Disconnect any devices or components from the circuit to isolate and accurately measure insulation resistance.

- Select the Right Voltage Level: Choose an appropriate voltage level on the insulation tester. Higher voltages are often used for high-resistance measurements.

- Apply Test Voltage: Apply the test voltage to the insulation and measure the resulting resistance. The megohmmeter will display the insulation resistance in megaohms.

- Interpret Results: Compare the measured insulation resistance with acceptable levels. Lower resistance values may indicate potential issues with the insulation.

- Record Results: Maintain a record of insulation test results for future reference and trend analysis.

By understanding the importance of insulation testing, recognizing the types of insulation testers available, and following guidelines on when and how to use them, individuals can proactively address insulation issues, enhance electrical safety, and ensure the reliability of their electrical systems.

Safety Considerations for Electrical Testing

Electrical work demands a high level of caution and adherence to safety protocols to prevent accidents and ensure the well-being of those involved.

In this section, we’ll underscore the paramount importance of safety in electrical work, provide tips on personal protective equipment (PPE) for electrical testing, discuss precautions when using various electrical testers, and highlight the significance of proper training and knowledge in handling this equipment.

The Paramount Importance of Safety

- Risk of Electric Shock: Electricity poses a significant risk of electric shock, which can lead to severe injuries or fatalities. Safety should always be the top priority when working with electrical systems.

- Fire Hazards: Faulty wiring, overloaded circuits, or damaged equipment can lead to electrical fires. Preventing these hazards requires a proactive approach to safety.

- Protecting Equipment: Electrical testing, if not conducted with care, can damage both the testing equipment and the circuits being tested. Adhering to safety guidelines safeguards both individuals and the equipment involved.

Tips on Personal Protective Equipment (PPE)

- Insulated Gloves: Wear rubber or insulated gloves to protect against electric shock. Ensure they are in good condition and appropriate for the voltage level.

- Safety Glasses: Protect your eyes with safety glasses to prevent injury from sparks, debris, or accidental contact with electrical components.

- Footwear: Wear insulated and non-conductive footwear to reduce the risk of electric shock.

- Arc Flash Protection Clothing: In situations where there is a risk of arc flashes, use flame-resistant clothing to minimize the impact of the flash.

Precautions When Using Different Types of Electrical Testers

Voltage Testers:

- Avoid Contact: Keep hands and body parts away from the probes or tips of voltage testers during testing.

- Inspect Before Use: Regularly inspect voltage testers for damage. Damaged testers can provide inaccurate readings and compromise safety.

Amperage and Wattage Load Testers:

- Current Ratings: Ensure that amperage and wattage load testers are used within their specified current ratings to prevent overheating.

- Secure Connections: Make secure connections when conducting load tests to prevent arcing or sparking.

Battery Testers:

- Battery Compatibility: Use battery testers that are compatible with the type of batteries being tested.

- Proper Connections: Ensure correct connections when testing batteries to avoid short circuits.

Insulation Testers:

- Isolation: Disconnect equipment from the power source before using insulation testers to ensure isolation.

- Appropriate Voltage: Choose the appropriate voltage level on the insulation tester to prevent damage to the insulation.

Proper Training and Knowledge

- Understanding Equipment: Proper training ensures users understand the capabilities and limitations of each type of testing equipment.

- Interpreting Readings: Knowledgeable users can accurately interpret readings, identify potential issues, and take appropriate corrective measures.

- Emergency Response: Training provides individuals with the skills needed to respond effectively to emergencies, such as electrical shocks or equipment failures.

- Compliance: Training ensures compliance with safety standards and regulations, reducing the likelihood of accidents and injuries.

Safety in electrical testing is non-negotiable. Emphasizing the importance of safety, using the right personal protective equipment, taking precautions with testers, and ensuring proper training and knowledge are crucial steps in creating a secure working environment.

By prioritizing safety, individuals can carry out electrical testing effectively while mitigating risks and hazards associated with this critical aspect of electrical work.

How to Choose the Right Voltage Tester

Selecting the right voltage tester is crucial for accurate and safe electrical work. Here, we’ll explore the key factors to consider when choosing a voltage tester, including type, range, and accuracy. Additionally, we’ll discuss how to match the voltage tester to specific tasks and projects.

Factors to Consider When Selecting a Voltage Tester

Type of Voltage Tester:

- Non-Contact Voltage Testers: Ideal for quickly checking the presence of voltage without direct contact. They are convenient for detecting live wires without touching them.

- Contact Voltage Testers: Require direct contact with the conductor to measure voltage. These are more traditional and often come with probes for physical contact.

- Proximity Voltage Testers: Utilize advanced technology to detect voltage even without direct contact. They offer an additional layer of safety and convenience.

Voltage Range: Ensure the voltage tester has a range suitable for the tasks you commonly encounter. Different models cater to low-voltage (e.g., household circuits) or high-voltage (e.g., industrial settings) applications.

Choose a tester with a wide enough range to cover the voltages you expect to encounter in your specific projects.

Accuracy: Accuracy is crucial for reliable voltage measurements. Look for a tester with a high accuracy rating to ensure precision in your readings.

Consider the tolerance level specified by the manufacturer. A lower tolerance level indicates higher accuracy.

Safety Features:

- Overvoltage Protection: A voltage tester with overvoltage protection safeguards the device from potential damage caused by voltage spikes.

- Auto Shut-Off: This feature conserves battery life by automatically turning off the tester when not in use.

Durability: A durable and well-built voltage tester can withstand the rigours of regular use. Look for models with robust construction and protective features to ensure longevity.

Ease of Use: Consider the usability of the voltage tester. Features such as a clear display, intuitive controls, and ergonomic design contribute to ease of use.

Some models may include additional features like a flashlight or audible indicators, enhancing usability in various working conditions.

Matching the Voltage Tester to Specific Tasks and Projects

- Residential Electrical Work: For routine home electrical tasks, a non-contact voltage tester is convenient and safe. Look for a model with a suitable voltage range for household circuits.

- Commercial and Industrial Projects: In industrial settings, where higher voltages are common, a contact or proximity voltage tester with a wider voltage range and robust construction is essential.

- HVAC Applications: HVAC professionals may benefit from a combination voltage and continuity tester for diagnosing issues in heating and cooling systems.

- Automotive Electrical Work: For automotive electrical work, a compact and versatile voltage tester with both non-contact and contact capabilities may be useful.

- DIY and Home Improvement: DIY enthusiasts can opt for a user-friendly voltage tester with features like a backlit display and audible alerts for added convenience.

Remember to check the manufacturer’s specifications and guidelines for each voltage tester model to ensure it meets the requirements of your specific tasks. Choosing the right voltage tester enhances efficiency, accuracy, and safety in your electrical projects.

Conclusion

In conclusion, “Watts the Difference? Choosing the Right Electrical Testers” has provided a comprehensive guide to navigating the intricate world of electrical testing.

We began with an exploration of various testers, from voltage testers to insulation meters, emphasizing the paramount importance of safety throughout. Delving into the functionalities of each tester, we highlighted the significance of understanding their applications and offered insights into the factors influencing the selection process.

As we close, we extend our heartfelt thanks to our readers for joining us on this informative journey. Remember, we continually update our online shop with the latest electrical testers, complete with reviews and descriptions.

To stay in the loop, sign up in the My Account section for our weekly email, ensuring you never miss out on cutting-edge tools and insights.

As you embark on your electrical ventures, always remember: “The only way to do great work is to love what you do.” – Steve Jobs.

Don’t miss out on the opportunity to connect with a community of like-minded individuals who are passionate about shopping, tech, lifestyle, hardware, and stationary products. Follow us on Facebook, X, and LinkedIn to stay updated on our latest product releases, tech trends, lifestyle tips, hardware reviews, and stationary must-haves. By connecting with us, you’ll have access to exclusive deals, updates, and the chance to engage in meaningful conversations with others who share your interests. We believe that these interactions will be a source of excitement and inspiration for your shopping and tech endeavours. So, take the next step and hit the follow button today!

Meet The Author

With over 23 years of full-stack development experience, I specialise in creating custom digital solutions that align with your business goals. Proficient in PHP, MySQL, JQuery, HTML, JavaScript, and CSS, I design user-friendly applications that streamline operations and improve data management. My entrepreneurial background gives me practical insight into business challenges, allowing me to craft solutions that are both efficient and strategic. In addition to development, I offer expertise in social media marketing and graphic design, ensuring a comprehensive approach to your digital needs. I am passionate about helping businesses grow through tailored, practical solutions that deliver real, measurable results.

Visit: https://quickfood.co.za/ for more!